Deionized water is a neutral drink that has had all its ions removed. It can be created by exposing conventional water to electrically charged resins, which attract salts and remove them from the water.

For years, it has been used in microelectronics and medicine. It is a good solvent for producing various products currently on the market.

Some people use deionized water in their homes, while some hesitate to buy water filters to produce one for their family.

This article discusses deionized water and its production. It also discusses the benefits and risks of using it at home or in the office, and provides tips for its use.

What Makes DI Water Necessary?

Deionized water is a true water blank, assuming the chemistry of whatever product is added. This has critical implications, especially for the medical industry.

When medical manufacturers create a product, water is almost always added. However, to ensure a chemically sound product, the water must not contain any impurities that could potentially change the product’s chemical composition.

For example, suppose a chemist wants to make a saline solution or another solution injected into the body.

In that case, their water needs to meet a standard called “water for injection,” which starts with deionized water. The saline formula is added to replicate the necessary solution.

If the water contains impurities or metals, such as copper or lead, it can cause adverse health effects for anyone who injects the product.

Other DI Water Applications

In addition to medical product manufacturing, DI water is used in facilities across various industries for a range of purposes.

For example, a glass manufacturer may require DI water for rinsing its product after completion. Using tap water would result in TDS deposits (calcium, magnesium, silica) on the glass surface.

For the biotech and pharmaceutical industries, bacteria-free water is essential. Any organic content in a solution or chemical mixture absorbed into a patient’s body could be harmful.

In specimen processing, where surgical instruments are cleaned, deionized water is used with a liquid or gas disinfectant and a microbial-free rinse to ensure the instruments are free of residual contamination and remain absolutely sterile. This is something that tap water cannot guarantee.

Deionized water has removed almost all its mineral ions, resulting in bacteria-free purified water.

In many industries, including the medical and pharmaceutical sectors, deionized water helps maintain product safety and integrity.

Deionized Water

The idea of deionizing water began years ago with scientists’ notion that water is better when pure.

Deionized water, also known as demineralized water, is water wherein all of its mineral ions, such as sodium, iron, calcium, copper, chloride, and sulfate, are removed. It is clean, safe, and tastes great. Also, it does not contain any chemicals or harmful toxins.

Big manufacturing firms, pharmaceutical companies, and laboratories use deionized water in their experiments and products.

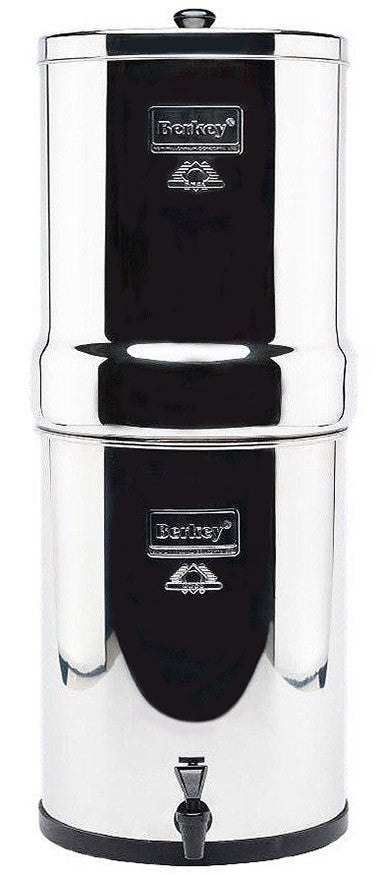

One can install a home water filter that uses direct osmosis to create deionized water. Although the system can be costly, the benefits can outweigh the price. It is also easy to maintain, as only a few accessories must be cleaned monthly.

The water filter can also be used in places like hospitals, offices, and schools where hard water is unsafe for drinking. Meanwhile, the ions lost in the process can be obtained by eating healthy fruits and vegetables.

Deionization is a chemical process that uses specially manufactured ion-exchange resins to exchange hydrogen and hydroxide ions for the dissolved minerals. The dissolved minerals then recombine to form water.

The deionization process can produce highly pure water, similar to distilled water, since most non-particulate water impurities can be removed by dissolving them in salt. Also, deionization does not cause scale buildup, which speeds up the process.

Conversely, deionization cannot remove uncharged organic molecules, bacteria, and viruses unless incidental trapping is used in the resin. As such, deionized water can still pose health problems.

However, specially made, strong base anion resins can remove even gram-negative bacteria. Furthermore, electro-deionization can be used to deionize continuously and inexpensively.

Meanwhile, there are three deionization processes: the counter-current, co-current, and mixed bed.

Co-current Deionization

Co-current deionization pertains to the water's original downflow process. In this process, the regeneration chemicals and the input water enter the top of an ion-exchange column and exit at its bottom.

The costs of concurrent deionization are higher than those of counter-current deionization due to the different regenerant usage.

Regenerate chemicals are diluted as they encounter the bottom or finishing resins in an ion-exchange column. As such, the product's quality is lower than that of a similarly sized counter-flow column.

Some companies still use this process today. Focusing on the flow of the regenerants within the ion exchange column can maximize its efficiency.

Counter-current deionization

Meanwhile, counter-current deionization has two major forms that require specific engineering internals.

The first is the up-flow columns. At this location, input water enters from the bottom, and the regenerants enter from the top of the ion exchange column.

Second, there is the up-flow regeneration. With this one, the water enters from the top while the regenerants enter from the bottom.

In these two cases, separate distribution headers must be tuned up. The input water flow and quality, desired product water analysis, and operation time between regenerations must be set accordingly.

Counter-current deionization is a more attractive method of exchanging ions among the three types of deionizing water. Chemicals or regenerants

can flow in the opposite direction towards the service flow. As such, less time will be needed than in concurrent deionization.

Furthermore, the quality of the final product can be as low as 0.5 parts per million. Indeed, there are various advantages of counter-current deionization. Some of these require low operating costs and minimal regenerant use throughout the process.

Mixed bed deionization

Lastly, mixed-bed deionization uses a 50:50 mixture of anion and cation resins. This mixture is combined in a single ion-exchange column. It also includes mixed-bed demineralizers for final polishing of the water, which can remove the last few ions before use.

Studies show that, with proper treatment, the water produced by mixed bed deionization in a single pass can be the purest of all water types.

Unlike large mixed-bed deionization units, small mixed-bed deionization units have no regeneration power. Big companies use commercial mixed-bed deionization systems with elaborate regenerant and internal water distribution systems.

In this system, a controller operates the valves and the pumps so regenerants can mix with the anions and resins in the ion exchange column. Note that each of these is regenerated separately and combined again during regeneration.

This system is used only when the company requires the highest water purity. It can achieve efficient, quality water through difficult, expensive regeneration.

Distilled Water versus Deionized Water

Distilled water and deionized water are often used interchangeably today, but they are different.

Distillation is one of the oldest forms of water purification and is still used. Distilled water is pure and uncontaminated, while deionized water is even purer.

First of all, deionized water is created through a series of intensive water purification processes.

After the initial water-cleaning process, the water passes through a reverse-osmosis membrane. Then, it passes through a special deionizing medium that removes the remaining ions.

After undergoing these intensive purification processes, deionized water can be pure or even purer than distilled water.

What is the difference between distilled and deionized water that makes consumers opt for distilled water? Even if the latter is as pure and clean as the former?

Water distillation is a much simpler and more convenient process than deionizing water. Here's a list of their difference:

-

Distillation and deionization are two ways of water purification that are far cheaper. For household use, there is no difference. Deionized water can be used for anything that traditionally requires distilled water. Even if it is labeled as ‘distilled water,’ it is probably deionized, not distilled.

-

While deionization removes most minerals and other inorganic ions, it does not affect organic substances or microbes. Distillation generally produces water of better purity but might not remove volatile organic compounds.

-

Ultrapure water is sometimes needed in laboratories, pharmaceutical industries, and other industries. Historically, the purest water was obtained by double distillation. However, several advanced purification methods can be combined to achieve even higher purity.

With the availability of countertop water distillation machines, it is easier to produce safe, pure water through this process than through deionization.

This makes it a far more popular option for people who want clean water without spending extra money on bottled water or an extensive purification process.

WHAT IS REMOVED FROM DEIONIZED VS. DISTILLED WATER?

Distilled water and deionized water are both very pure. However, the water's purity before it undergoes treatment matters. The deionization process, for example, only removes ions—charged non-organic particles—from the water.

First, the water should be filtered to remove organic material. Additional filtering with a reverse osmosis (RO) system will remove many additional contaminants. This leaves only a small amount of ionized minerals for the DI system to remove.

Water distillation, on the other hand, can remove more impurities than just ions. This process removes nearly all minerals, many chemicals, and most bacteria.

However, that doesn't mean it removes everything, especially if the water contains volatile organic compounds and other contaminants. These impurities will evaporate and stay in the distilled water.

As with deionized water, pre-treatment filtering is an important step.

How to Deionize Water

Simply put, deionized water is water with all its ions removed. This is important because once organic materials are removed from the water supply, most dissolved impurities are ions, such as calcium, sodium, and chlorides.

An ion is a molecule with a positive or a negative charge; iron ions, for example, have a positive charge. One way to effectively purify water is to remove these ions and replace them with hydrogen (H+) and hydroxide (OH-) ions, which combine to form water.

Check out our page on DI water to learn more terms and definitions related to deionization.

Are you curious about how to make deionized water? Before passing through a deionization (DI) system, water is usually filtered and pushed through the reverse osmosis (RO) membrane.

These pre-filtering steps remove organic matter and contaminants, leaving the water very clean before it enters the DI system.

Two ion-exchange resins are used to deionize the water. Due to the resin's greater affinity for other ions, positively charged ions (cations) and negatively charged ions (anions) are exchanged for hydrogen (H+) and hydroxyl (OH—) ions, respectively.

After passing through both types of resin at least once, all that's left is highly purified water. Once the exchange capacity is depleted, the resin bed is regenerated with concentrated acid and caustic. Physical displacement strips away accumulated ions, leaving hydrogen or hydroxyl ions in their place.

TYPES OF DEIONIZERS

Once you know how to make deionized water and what it's used for, you need to understand the different types of deionizers. Each deionizer system is effective, but some are better suited to specific industries or purposes.

There are four basic types of deionizers:

- Disposable cartridges

- Portable exchange tanks

- Automatic units

- Continuous units

A two-bed system uses separate cation and anion resin beds. Mixed-bed deionizers utilize both resins in the same vessel. Mixed-bed deionizers produce the highest quality water, but two-bed deionizers have a larger capacity.

Both cartridge and portable exchange tank units can be used until the resin is exhausted, at which point they are replaced. Automatic units are permanent fixtures, and the resin is regenerated on-site.

Continuous deionizers, mainly used in labs for polishing, do not require regeneration.

Where Can You Use Deionized Water?

Deionized water dissolves drugs sold to the general public as medicines in microelectronics and pharmaceutical companies. It is also a key ingredient in the manufacturing of healthcare products and cosmetics.

Also, deionized water is a good solvent for ceramic, glass, wood, prick, and other materials. Here are other uses of deionized water today:

-

Preparation of chemical mixtures and solutions in the laboratory.

-

Preparation of electrolytes for alkaline and acid-based batteries.

-

Dilution of concentrated anti-freeze chemicals.

-

Final rinsing of printed circuit boards, washing the equipment from alkalis and acids after processing the technological operations in the electronics industry.

-

Refueling the car's glasswashers

-

Topping up the cooling system. Deionized water will not create salt deposits in the system.

-

Flushing cooling systems out of automobiles.

-

It can be used in perfumes.

-

It can be used as a detergent.

-

Refilling household steam and iron devices can help prevent mineral deposits.

-

Other industrial processes require pure water.

Nowadays, deionized water as a cleanser is a new technique. It does not use any chemicals; instead, it uses water.

Advantages of Using Deionized Water

Deionized water is the water of choice in many factory and manufacturing settings because it helps avoid salt buildup on machinery.

Deionized water can be used to cool and lubricate machines and other equipment in industrial settings.

Deionized water can be used to manufacture cosmetics, medicines, and processed foods.

Meanwhile, some health experts recommend using deionized water only for short-term detoxification. However, if you choose to detox this way, you should seek the advice of a health expert. According to the World Health Organization, they can monitor your progress to ensure you don’t overdo it.

If you are concerned about the ions lost in deionization as you drink water, you can easily obtain them by eating a well-balanced meal.

Converting Tap Water into DI Water

Deionization exchanges all the charged ions in tap water for Hydrogen and Hydroxyl ions, helping form the water molecule H2O.

The deionization or ion exchange process results in true purified water, which is “blank”—nothing but water in its purest form.

The deionized water then takes on the characteristics of any solution or chemistry added to it. A temperature-compensated resistivity meter will measure approximately 18.2 megohms of resistivity for good-quality deionized water.

So how do we get there? It involves a deionization process that uses high-purity resin to initiate an exchange cycle, removing unwanted ions from the water. However, the equipment configuration for this process varies widely depending on several factors.

Risk of Using the Deionized Water

Deionized water can be harmful to your health. Because of serious concerns about its effects, it is best used only for industrial purposes.

Here are some of the risks that you should take note of:

Absorb Ions in the Body

First, it lacks ions, but drinking it can help your body absorb the ions. It can also steal minerals from your tissues, such as magnesium and calcium, which are easily absorbed by deionized water.

Although water is not an important source of magnesium and calcium, it can help contribute to people's daily needs. As such, drinking deionized water can limit your intake of essential nutrients.

Note that magnesium and calcium are important for bone development and are also good for the heart.

Deionized Water Tastes Bad

Deionized water is free of ions and minerals, so it might taste bad. Your taste buds may adjust to its taste over time.

However, you tend to seek out other beverages, such as soda and carbonated drinks, which are bad for your health. Also, unlike other types of water, deionized water is not a good beverage for quenching your thirst.

Risk of Toxic Metals

If you get your deionized water from the tap, you may be at risk of contamination with toxic metals. Because it is less stable, deionized water is more prone to attracting metals in plums than mineralized water.

Regular water contains magnesium and calcium, which help prevent the formation of toxic substances in drinking water, and these aren’t present in deionized water. Calcium and magnesium stabilize the water and act as antitoxic substances.

Tips for Switching to the Use of Deionized Water

Since bacteria and viruses can still be present in deionized water, you can ask your local water filtration unit provider for the best unit to strain them effectively.

Ask about the ideal maintenance of your home water filtration system and the appropriate cleaning measures to use.

Eat a well-balanced meal or take dietary supplements, such as multivitamins, to replenish the lost ions in water after drinking deionized water.

Conclusion

Although deionized water can be consumed, the Illinois Department of Physics warns that not all deionized water is suitable for public consumption.

This is because the water in laboratories and large manufacturing companies contains specialized resins that remove the ions. These resins can have harmful effects on the body.

However, if the water has a label that says it is safe to drink, you can have it. Otherwise, don’t take products you are not 100% sure are safe. Also, make sure to eat a balanced diet so that the nutrients in your food replace the ions lost during water purification.

The water you drink is decontaminated and filtered to make it safe. However, it contains minerals, also referred to as ions, such as sodium, magnesium, and iron.

Deionization removes minerals, creating purer water. While there are uses for deionized water, removing minerals is not always the best approach.

If you plan to install a water filter that produces deionized water, always consult an expert and learn about the pros and cons of this type of water.

← Older Post Newer Post →