Water has a long journey before it reaches your glass. It gets collected, treated, and filtered so many times along the way.

One of the most critical parts of that process happens inside your water filter. Not many people know about this. But, there's this black, grainy material that silently cleans your water.

And that material, as the title suggests, is known as activated carbon. The whole gist is simple. It physically binds to "unwanted" substances in your water.

These substances are the harmful ones that make your water taste or smell bad, or even make it unsafe to drink. So, activated carbon basically "washes" them out. Many filters actually contain it.

But take note that not all kinds are equal. Some are manufactured from coal, some from wood, and others from coconut shells.

Nowadays, coconut shell activated carbon (CSAC) is increasingly preferred for many premium water filtration systems.

It is made from coconut shells, which are considered waste (we'll talk more about this later), making the substance effective and environmentally friendly.

Because of its dense structure, it’s very good at catching tiny particles and chemicals. Yes, even some particles that other materials might miss.

So, this is a really critical component of water filters. Especially if you want to ensure safe drinking water at home.

IN THIS ARTICLE, we are going to talk about what CSAC is, how it is made, and why it functions better in contrast to other types of activated carbon.

We will look at the contaminants it can remove, its role in enhancing taste and purity, and how it's used in modern filter products such as carbon blocks and gravity filters.

Let's begin by understanding what coconut shell-activated carbon is and why it has become such an important part of modern clean water systems.

What is Coconut Shell Activated Carbon (CSAC)?

As we mentioned above, coconut shell activated carbon is a type of activated carbon. It is produced from coconut shells.

And it’s actually a porous carbon material with a vast surface area. This allows it to trap unwanted substances that move through it.

Again, the idea is simple. The more surface area inside the carbon, the more space there is for impurities to stick.

We'll talk more in a bit about the steps for making CSAC. But, definitely, it opens millions of microscopic pores inside carbon.

After the process, you get a high-density, highly resistant material. Plus, it has strong adsorption properties.

Suppose you're wondering why coconut shells. Well, it's because of their high carbon content. And not to mention the structure's complex (and incredibly dense) nature.

Ultimately, coconut shell carbon has a good pore size distribution. Good enough to make everything stick.

Many people would vouch for it. It performs better in removing small organic chemicals and volatile organic compounds from water.

It also exhibits a cleaner pore structure and lower impurity levels than coal-based activated carbon. This is why coconut shell is king.

It is also used in many carbon filters due to its high adsorption capacity and long lifespan.

Coconut shell carbon is used in a wide variety of water filtration and environmental remediation processes.

-

It helps eliminate taste, odor, and toxic elements in drinking water.

-

It is also employed in gas purification, catalyst support, and precious metal recovery.

-

It is even used as an electrode material in some fields of chemical engineering.

Coconut shell really offers both performance and environmental sustainability. You don't even have to pick from the two. It delivers both.

Hence, it has become a key ingredient in modern water filters and other purification systems.

How CSAC is Made: from Shell to Filter Media

• Sourcing the raw material

Of course, we start with the raw material itself. Coconut shells are usually derived from the food industry.

Typically, it is a by-product after the meat and water are used. That's sustainability in itself, right?

Many of these shells come from tropical countries such as the Philippines, Indonesia, and India. These are the countries where coconuts are readily available.

• Carbonization (pyrolysis)

Now that we have secured the raw material, we proceed to the carbonization process. It's sometimes called pyrolysis.

The gathered shells are first cleaned. And then they are heated in the absence of much oxygen or in an inert atmosphere.

In this part, volatile components are removed. After which, they leave behind a carbon-rich material called coconut shell charcoal.

It is done at very high temperatures. Think between 600 and 900 degrees Celsius. But this is actually required to stabilize them enough for the next step (discussed below).

• Activation step: physical and chemical.

This is the process by which coconut shell carbon gets its adsorption capabilities. There are two usual methods of activation for coconut shell carbon: (1) physical and (2) chemical.

Let's start with the physical activation. It is actually carried out at high temperatures using steam or carbon dioxide.

Chemical activation involves using an activating agent, such as phosphoric acid or potassium hydroxide, at lower temperatures.

Both techniques yield a complex porous structure within the carbon. They can trap small molecules and, hence, certain chemicals effectively during water purification.

• Post-treatment and finishing

After activation, it undergoes a post-treatment. It is washed to remove residual chemicals. Then, finally, it is dried and processed into various forms.

Think of granular activated carbon, powdered activated carbon, or shaping carbon blocks. These can ALL be prepared and used in carbon filters.

• Quality control and certifications

Of course, the final material has to have good mechanical stability and consistent surface properties. That's why shell-activated carbon is tested for quality and performance before being used in water treatment systems.

Most manufacturing companies employ international standards such as NSF and ANSI for water-grade carbon materials. They check on the adsorption capacity, surface characterization, and pore volume to ensure it meets the safety and efficiency targets.

This process is still lower in more "environmentally friendly" terms compared to mining coal or producing synthetic carbon materials, even though it requires high temperatures and energy.

The addition of renewable coconut shells and the recycling of the spent activated carbon will go a long way in reducing the carbon footprint.

Such steps have made coconut shell-activated carbon one of the most practical and sustainable options for modern water filtration and environmental remediation.

CSAC vs Coal-Based (and Other) Activated Carbons

|

|

Coconut Shell Carbon |

Coal-Based Carbon |

Wood / Other Biomass Carbon |

|

Feedstock |

Renewable coconut shells (by-product) |

Non-renewable fossil coal |

Renewable wood, peat, nutshells |

|

Pore Type |

Mostly microporous |

Mix of micro + mesopores |

Mainly mesoporous |

|

Ash / Impurities |

Very low |

Higher |

Moderate |

|

Hardness / Strength |

High; low attrition |

Moderate |

Soft; wears faster |

|

Adsorption Focus |

Small molecules, taste, odor, chlorine |

Broad organics, gases |

Color, larger organics |

|

Environmental Impact |

Low footprint, renewable |

High emissions, mining impact |

Renewable but lower yield |

|

Typical Uses |

Drinking water, air, and household filters |

Industrial water, gas treatment |

Food and specialty uses |

|

Cost / Market |

Premium, long life |

Lower cost; standard |

Variable; niche |

1. Feedstock differences

Activated carbon may be manufactured starting from a variety of feedstocks.

Think like coal, wood, and coconut shells.

Each feedstock gives the carbon different surface properties and adsorption behavior.

Of these, coconut shell-based activated carbon has gained a strong reputation for its efficiency, especially in water treatment and environmental sustainability.

Coal-based activated carbon is manufactured from mined coal, a non-renewable resource. It generally contains more ash and impurities, including heavy metals.

Coal carbon has a broader pore structure. That's why it can be well-suited for applications involving trapping large molecules in the gas phase.

But, there's a little caveat. It is less effective in capturing small organic chemicals present in drinking water.

On the contrary, coconut shell carbon exhibits a narrower pore-size distribution. It even has a higher micropore volume ratio.

That's why it is very effective at capturing small volatile organic compounds, pesticides, and chlorine disinfection by-products in filtration applications.

2. Physical/structural differences

CSAC is more complex and denser. So, what does that mean? Well, it just means it lasts longer in carbon filters and resists breakdown during use.

It also has higher mechanical stability and chemical stability. It is very stable under constant water flow.

Many filter manufacturers actually prefer it. It keeps its structure longer, reducing replacement and maintenance costs.

3. Performance in water filtration

Among porous carbon materials, coconut shell activated carbon has one of the largest surface areas, as evidenced by its adsorption capacity.

The activation process creates millions of microscopic pores, increasing the points of contact with contaminants.

Its high surface area and uniform pore volume make it ideal for removing organic impurities and certain toxic substances.

This, therefore, explains why it finds wide application in drinking water purification, gas purification, and environmental remediation.

4. Environmental / sustainability comparison

Coconut shell-activated carbon is cleaner from an environmental perspective. We couldn't stress this enough.

It uses a renewable raw material that is mainly considered "waste" in the food industry. Therefore, it reduces waste and contributes to a sustainable future.

Coal mining has a higher carbon footprint and greater environmental impact through extraction, energy consumption, and emissions.

Shell-activated carbon is still produced at high temperatures. But honestly, its overall impact from feedstock derived from existing agricultural waste is lower.

Because of these differences, coconut shell carbon is often considered a superior material for water filtration and industrial purification.

Eco-Friendly Origins and Sustainability of CSAC

First, it uses an abundant resource: coconut shells.

The shells are a natural byproduct of the coconut industry.

So, think like the Philippines, Indonesia, and India.

Second, it's not being wasted or burned.

The shells are gathered and transformed into a highly valuable filtering medium.

Using agricultural waste reduces stress on natural resources. Plus, it enhances local economic conditions. And it's all because coconuts serve dual purposes: both as food and for oil production.

Third, the environmental impact is much lower than that of others.

The carbon footprint will be less because mining or the extraction of any non-renewable resource is not required. The coconut shell is renewable and biodegradable.

It is a very suitable feedstock for sustainable carbon materials.

Its high density and high carbon content mean less material is required to produce carbons with excellent adsorption capacity and surface area.

Fourth, the activation itself also contributes to the sustainability of the process.

Physical activation by steam or carbon dioxide creates the porous structure without added chemical waste.

Though these methods are indeed very energy-intensive, the toxic by-products are minimal. Some manufacturers even recover heat or reuse steam from such processes to reduce energy consumption.

With careful use, chemical activation can also achieve high yields at lower temperatures. And so, it could be managed to reduce waste and emissions.

Lastly, it's a form of recycling that helps reduce both environmental and economic costs.

In industries such as gold recovery and gas purification, where activated carbon is used cyclically, regeneration is an integral part of the carbon's life cycle.

CSAC in Modern Filtration Products

6.1 Gravity filters

These filters allow water to move downward through some filter medium without pumps or electricity. In these systems, water either passes through a carbon block or a bed of granular activated carbon.

That's honestly why coconut shell carbon is SO ideal. Because of its dense structure and strong adsorption property.

Therefore, organic chemicals, VOCs, and unwanted odors that affect taste are removed. It also performs well over time, standing mechanically stable even on portable or off-grid setups.

Many travel and household gravity systems rely on carbon made from coconut shells. They offer low maintenance and great performance in the purification of drinking water.

6.2 Carbon block cartridges

Another common form is the carbon block filter. In this, coconut shell activated carbon powder or granules are compressed into a solid block using a binder.

This design allows for a longer contact time between water and the porous structure, improving the removal of small contaminants while reducing channeling or uneven flow.

6.3 Mixed-media and hybrid filters

More advanced filters combine CSAC with other materials, such as KDF, ion-exchange resins, ceramics, or UV lamps. Such layered configurations can target different contaminants.

The coconut-shell carbon layer is typically the first layer. It serves to absorb toxic substances, chlorine, and odors before water reaches the other stages.

6.4 Premium brands and market positioning

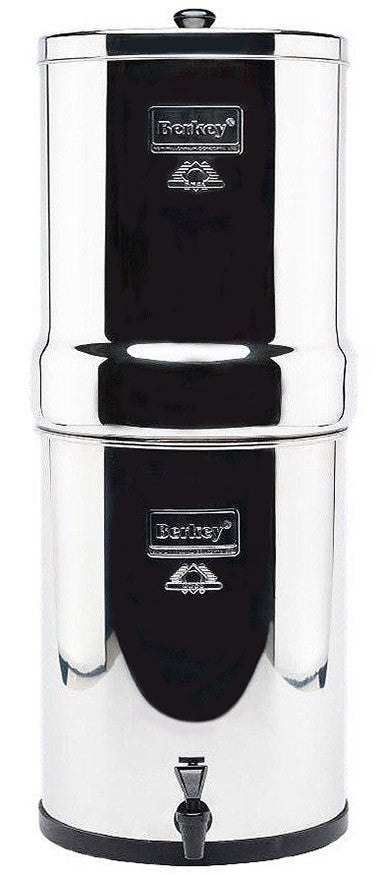

Several high-end filter brands, such as Berkey, tout the use of coconut shell-activated carbon in their central systems.

Consumers looking for clean, pleasant-tasting water can look for details on product labels about "coconut shell carbon" or "silver-loaded activated carbon". These products are good to go. They're certified for safety and performance by certifications like NSF/ANSI.

The new Phoenix Gravity New Millennium Edition™ Filters deliver exceptional performance with genuine NSF/ANSI certifications and a premium media blend made from CTC-60 coconut-shell granular activated carbon derived from natural coconut husks.

Engineered with millions of micro-pores for superior adsorption, these filters target a wide spectrum of contaminants—including PFAS, heavy metals, VOCs, and chlorine—while maintaining strong flow rates and long service life.

Designed as reliable, high-quality gravity-fed filtration solutions, they deliver clean, great-tasting water backed by rigorous standards and advanced carbon technology.

6.5 Use in developing regions and emergencies

Other uses for CSAC filters are humanitarian programs and off-grid areas. Indeed, these provide safe drinking water without electricity and hence are ideal for rural communities or disaster relief.

Since they are durable and low-maintenance, they are used and trusted in harsh environments.

6.6 Future trends

Research continues to improve the range of coconut-shell-derived activated carbon, with innovations in impregnated carbon, such as silver-impregnated carbon, to limit microbial growth in the adsorbent and hybrid systems. This is where CSAC is used in combination with nano-composite membranes.

Buying Guide & Consumer Considerations

When choosing a water filter powered by coconut shell-activated carbon, it is important to know which features to look for. This is key to getting the real deal!

What to look for:

Check the technical description of the filter for the words "coconut shell activated carbon" or "coconut shell-based carbon."

NSF/ANSI-certified filters (as mentioned earlier) must meet stringent safety and performance criteria.

Check the flow rate and contact time. A slightly slower flow often results in better adsorption, therefore, more efficient organic impurity removal.

Maintenance and life-span:

All carbon filters have a limit. Over time, adsorption properties weaken as pores fill with impurities. Check the rated capacity in liters or months and plan for replacement.

A few systems allow backflushing or cleaning, but most rely on cartridge swapping. Store spare filters in a cool, dry place to preserve quality.

Matching the filter to your needs:

Select based on household size and source of water.

For city water, Taste & Odor control may be sufficient, while well/rural water may require the addition of CSAC filters combined with sediment or UV treatment.

Eco-friendly decisions:

Choose filters containing long-life cartridges to reduce waste. A few systems allow the recycling or composting of uncontaminated used carbon.

Check where the filter is made and how far it ships. This adds to its carbon footprint.

Cost and value:

Coconut-shell carbon filters are more expensive than standard coal-based activated carbon filters.

But they still last longer and offer better taste and purity. Such durability will mean less waste in the long run; thus, it is a prudent and viable investment in sustainability.

Final Thoughts

Coconut shell activated carbon is an excellent example of how nature and technology can work together. All for cleaner water.

Even with discarded coconut shells, you can make a material with strong adsorption power and a low environmental footprint.

Its fine pore structure helps remove unwanted taste, odor, and many organic compounds that affect water quality. Giving you, all in all, a better drinking water.

That's why it's often found in premium water filters and carbon blocks used at home and in the field.

Although CSAC on its own does not remove all types of contaminants, when used with other treatment stages, it dramatically improves purity and taste.

Systems from brands like Berkey show how well this material performs when combined with a durable design.

← Older Post Newer Post →