When you turn on your tap, the water looks clear. It fills a glass fast. It tastes normal. But honestly, there's more to it than what you see. There are lots of things in that water "too" small to see.

Some homes have traces of chlorine from treatment plants. Others may have residual pesticides from farming. And some deal with PFAS and VOCs. These are long-lasting chemicals that can migrate into water supplies.

People use filters at home because they want drinking water that feels safer. The carbon filter is one of the most common options. It does not look special. Actually, it's just some sort of block or a set of small black grains.

But many households trust it because it can reduce a wide range of unwanted substances.

IN THIS ARTICLE, we will explain how that happens. We will go through the idea of adsorption. It's the key process behind carbon filtration after all.

We will also show (or at least talk about) how carbon has tiny pores that pull contaminants toward its surface. After that, you will see how this method compares with simple mechanical filters that only block particles by size.

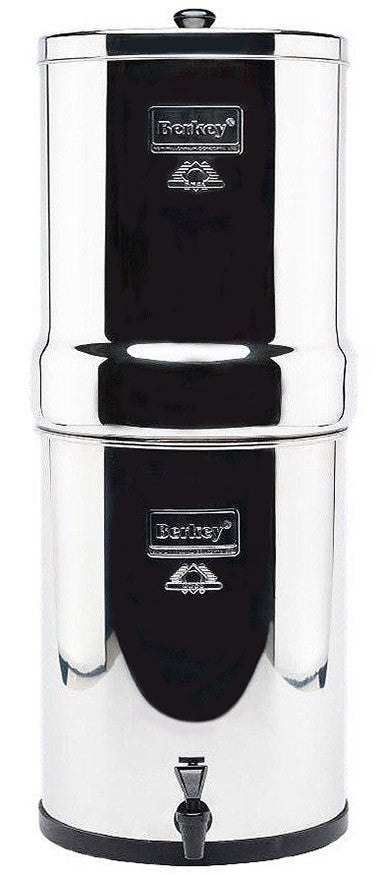

To make everything concrete, the article will look at the Black Berkey Elements as a real example of a carbon-based system. By the end, you will understand what these filters actually do. And of course, the reason why many people rely on them for everyday drinking water. Who knows? It may work for you, too!

Basics of Carbon Filtration

A carbon filter uses activated carbon as the primary material (hence the name). Some people also refer to it as activated charcoal, though.

• Forms of Carbon Filters

It can come in many forms. There is granular activated carbon, powdered activated carbon, bead activated carbon, woven carbon, extruded activated carbon, and even activated carbon cloth.

They look different. But honestly, they follow the same idea.

The carbon has a porous structure, giving it a very large surface area. That surface becomes the space where unwanted substances stick.

• Process of Carbon Filters

It starts as raw material. Think about coconut shells, coal, or other carbonaceous material. Then it undergoes a process called carbonization.

During the process, most of its non-carbon parts are removed. Next, the material is activated. This happens either through steam activation or through chemical activation.

Both methods create millions of tiny pores. Yes, both the atmosphere and the action of certain chemicals develop the pores.

That is how simple carbon is turned into active carbon. That is, the one that has powerful adsorption properties.

Adsorption vs Absorption

Knowing the difference between absorption and adsorption is important. And that's because most people (and understandably so) tend to get them mixed up.

Absorption occurs when a substance enters the bulk of material. Think of a sponge, for instance.

The water goes inside it, right? Meaning that the liquid becomes part of the whole sponge. That's what absorption is all about.

Adsorption is different, though. It occurs on a solid surface. Let's take a dust, for example. And let's say it settles on a table.

The dust does not enter the wood. It stays on top. The same idea applies to an activated carbon filter.

Contaminants move toward the adsorbent substance. And yes, they stay on the solid surface of the carbon. They do not flow into the carbon like water entering a sponge. That's the difference.

If you draw a quick diagram, you can show two shapes. One shape absorbs a droplet into its center. At the same time, the other shape keeps the droplet on the outside layer.

That image shows quite clearly. One is bulk uptake. The other is surface adhesion.

Adsorption can happen through different mechanisms. Let's get into detail, shall we?

(1) Physical adsorption or physisorption

It is based on weak forces such as van der Waals attraction. But it's not the only one, though.

Honestly, most organic molecules, volatile organic compounds, and gas molecules follow this same "route." Such light forces cause them to settle on the surface of activated carbon.

It actually occurs more in water filtration systems. And that's just because it goes along with the porous structure of the particles of activated carbon.

(2) Chemical adsorption or Chemisorption

This type forms stronger bonds. Covalent bonding can occur between the molecule and the carbon atom.

There are definitely ways to increase this effect. For example, chemical treatments. It works especially well with some activated carbon complex materials.

There's this thing called impregnated carbons. You'll see more of that "effect" in here. Especially those that support more active chemical reactions.

Both physical and chemical adsorption appear in industrial applications. Think about gas purification, solvent recovery, and air purification.

In water filters, the emphasis is on adsorption at the surface.

Because of its pore size distribution, activated charcoal has many adsorption sites throughout—organic impurities, organic chemicals, and other substances that pass through hold onto these sites.

The surface diffusion moves each adsorbate molecule deeper into the pore network until adsorption equilibrium is reached. All that depends on adsorption kinetics, mass transfer, and surface coverage.

Some systems even model it with the Langmuir isotherm. But honestly, you don't have to go into the math to get the gist of it.

The Science of Micropores and Surface Area

Externally, activated carbon appears to be a solid. Internally, though, it contains very few spaces.

These spaces are formed during activation. Yes, the same process we talked about above.

During the process, the material is heated, and micro-, meso-, and macro-pores open.

Each type has a different size.

-

Micropores are the smallest.

-

Mesopores fall in the middle range.

-

Macropores are large and serve as entrance halls.

These pores matter a lot. Why? Since they create a huge internal area. One gram of activated carbon can cover more than 3,000 square meters of surface area.

The thing is simple. The more internal area the carbon has, the more room it gives to contaminants that need a place to settle.

There are many ways pollutants can enter the pores, actually. We have seen where it drifts through water due to Brownian motion.

Also, some movement due to small pressure changes. And from time to time, we have pore diffusion into deeper spaces. When they reach a surface inside the carbon, they can stick.

Weak forces pull that in. The van der Waals we mentioned above and other natural attractions. Sometimes, stronger bonding is possible. It's really the true chemical adsorption. But of course, it depends on the carbon's design. And finally, the treatment used during production.

Each pore size plays a role. Micropores trap small organic molecules and gas-like impurities. At the same time, mesopores hold mid-sized contaminants. That's why pore size matters a lot.

Macropores help guide larger particles into the inner network. A good filter has the right balance. If the pores are too small, the flow slows down. But then again, if they are too large, the carbon loses effectiveness.

Designers match pore sizes with the type of water and the expected load of impurities. All these pores act simultaneously. Water passes through the carbon. The inner walls draw in various molecules. After some time, the carbon becomes saturated.

At this point, the filter should be replaced. But in its "freshness," that high surface area translates into strong pulling power.

This is why many household filters use activated carbon as either the first or main step. The structure is simple, really. But in itself, the internal surface makes it effective.

How Adsorption Removes Specific Contaminants

Activated carbon is effective for many kinds of contaminants. Each behaves differently in water. Some attach to the carbon through weak forces. Some react with the surface. Some stay longer because the pores match their size and shape.

• VOCs are a common group.

These are non-polar organic compounds. They tend to settle into the hydrophobic pores of activated carbon. Van der Waals forces pull them in. Yes, we're back to that word again.

These forces are light. But honestly, they're strong enough to withstand VOCs because their pores provide many points of contact. Carbon filters help reduce the smell and taste issues caused by these compounds.

• Chlorine follows another path.

It can land on the surface. But then again, activated carbon can also help in breaking it down. A light redox reaction happens on the carbon.

The chlorine gets neutralized. This reaction makes the water taste cleaner. This is one of the reasons many homes rely on carbon filtration when tap water has a strong chlorine smell.

• Some pesticides and pharmaceuticals also enter the pores.

Many of these molecules are adsorbed physically. Some can form stronger bonds, which are closer to chemical adsorption.

The carbon can hold them well because these molecules often match the pore size of the micropores and mesopores. A matching pore size makes the process more efficient.

• PFAS are more challenging to address.

Under many environmental conditions, these kinds of chemicals remain stable. They do not tend to break down or degrade easily. But reduction is nonetheless possible with activated carbon.

PFAS have longer chains that can attach to the carbon surface. The surface chemistry of the carbon helps slow them down and hold them. Not perfect, but many systems still use carbon as a first step in PFAS control.

• Heavy metals behave differently.

Some stick to the carbon through weak interactions, while others need a carbon that has been treated to support stronger bonding. That's why not all carbon filters can deal with every metal. It is a question of the match between the metal and the surface treatment.

Adsorption has limits. The carbon fills up over time. When the pores become full, the filter reaches saturation. After that, contaminants start to pass through.

This is called a breakthrough. The filter may still look clean on the outside. But if you look inside, the pores can no longer hold more molecules.

Some industrial systems can regenerate carbon. High heat brings back the surface area. Chemical washing can also help in certain cases.

For home use, replacement is usually easier. Once the filter is spent, a new cartridge keeps the system running well. Not that much of a change, honestly.

Waiting too long lowers water quality because the carbon loses its adsorptive capacity. Activated carbon is flexible but performs best when it's fresh.

Its strength comes from the pores and the natural attraction between the surface and the water molecules. When pores stay open, the filter performs well. When they fill up, it is time to replace the system's carbon bed or cartridge.

Comparison with Mechanical Filtration

The principle of mechanical filtration is straightforward. Water passes through a material with fixed pores. Everything larger than those pores gets caught.

You see this in sediment filters, microfilters, and ultrafilters. The visible particles of sand, rust, silt, and such are caught. And so, they remain behind because they cannot fit through the pore opening. That's what this all means.

Carbon filters are quite different. They depend neither on fixed pore size nor on 'blocking' of debris. Instead, they rely on surface-based capture.

The molecules move across the surface of the activated carbon and stick to the adsorption sites. It works at a molecular level. And that's why carbon can target many dissolved contaminants that mechanical filters can't capture.

Mechanical filters are readily measurable. If a filter is rated at one micron, then anything bigger than that stays out. The result is predictable.

These types of filters also have a longer life when it comes to handling dirt because they only deal with physical particles. They cannot, however, remove many chemical pollutants.

Dissolved organic molecules, volatile organic compounds, and chlorine will just pass through because they are too small or they don't interact with the surface.

Carbon filters pick up where mechanical filters fall short. They can adsorb organics, VOCs, and many chemical toxins because these types of molecules bind to the activated carbon.

The tradeoff is in capacity. Over time, the surface fills up. Sometimes, flow can also be reduced when the water requires a longer contact time.

When carbon becomes saturated, it becomes a problem. That's because it can no longer pull contaminants. And so, it must be replaced.

Most good systems mix both methods. Mechanical pre-filtering protects the carbon by catching the larger particles first. This keeps the carbon pores clear, extending its working life.

Beyond that first stage, water comes into contact with activated carbon, which removes molecules that cannot be filtered by mechanical filtration. Both steps work well because each focuses on a different part of the job.

Case Study: Black Berkey Elements

Black Berkey Elements demonstrate how the science of activated carbon works in a real system. New Millennium Concepts manufactures them. Meaning, they use a blend of media packed into an excellent matrix.

Inside that matrix are millions of microscopic pores. Water moves through those pores at a slow, steady pace because the system relies on gravity rather than pressure.

First is the microfiltration layer of protection. The path inside the element twists and narrows several times. This is what people refer to as the “tortuous path.”

It forces water to make those tight bends. Bacteria, cysts, and sediment get caught along the way because they cannot slip through the tiny openings.

This is actually what gives the system a strong physical barrier. And that's even before the carbon surface starts working. Sounds reliable.

Adsorption also plays a significant role. Carbon within the element attracts contaminants to its surface. Most of the VOCs, solvents, and many organic molecules settle into the pore network.

The surface creates an ionic barrier that helps hold these molecules in their place.

Some stay by physical attraction. While others really stay through light chemical interactions.

Then, there is ion exchange. The element has resin that trades heavy metal ions, such as lead or mercury, for lighter ions.

This is where the filter component works more like "absorption," since the resin captures ions within its internal structure. In this specific step, you can reduce the metals that simple carbon cannot always handle on its own.

Also, the design gives everything more time to work. Since the water is not forced through at high speed, the molecules are in contact with the carbon much longer.

More contact time means better removal. This is one of the reasons Berkey units perform so well with such a wide range of contaminants.

Real-World Considerations & Challenges

Carbon filters do not last indefinitely. Their effectiveness depends on several factors. Of all things, water quality plays a significant role.

If your water has a high load of sediment, chemicals, or organic matter, the pores fill faster. Flow rate is another factor. The faster the water moves, the less time molecules spend in contact with the carbon.

Over time, the adsorption sites become saturated. Once that happens, the filter cannot remove contaminants as well. Some carbon filters are reactivatable.

In an industrial system, the surface can be renewed by heat or chemical treatment. Generally speaking, the regeneration of carbon filters in homes is limited.

For instance, Berkey's instructions recommend that elements can be primed or cleaned. For example, scrubbing the outer surface and flushing with water helps maintain flow and adsorption performance.

But eventually, even well-maintained filters need to be replaced. That's just how it goes. Cost is another consideration, of course. Activated carbon media in granular, bead, or extruded form does indeed have a cost.

Also, replacement cartridges add up over time. That said, the health and water-quality gains often outweigh the costs. Cleaner water tastes better, removes harmful chemicals. And ultimately, it can decrease the exposure to volatile organic compounds, pesticides, and heavy metals.

It's a reasonable investment, especially where tap water quality may vary. Still, safety and regulation are key.

Understanding these considerations will help ensure the filter works as we intended. And finally, to ensure they really provide safe and reliable water. After all, that's what we're all after, right?

← Older Post Newer Post →